Most WooCommerce store owners focus on configurator sales benefits but miss the massive cost savings - often $750+ per week in eliminated manual work and operational inefficiencies.

A properly implemented WooCommerce product configurator automates pricing calculations, prevents inventory disasters, and eliminates hours of manual order processing - transforming cost centers into profit drivers.

Key Takeaways:

- WooCommerce configurators eliminate $750+ in weekly hidden costs

- Automated pricing saves 15+ hours weekly on manual calculations

- Smart inventory management prevents costly overselling disasters

- Customer service efficiency improves by 78% with clear orders

- Includes 3 real case studies with full ROI calculations

- Bonus: Free ROI calculator to estimate your savings

What You'll Learn:

- The Hidden Cost Crisis in Custom Product Sales

- 7 Major Cost Centers WooCommerce Configurators Eliminate

- Real Business Cost Savings (With Actual Numbers)

- ROI Calculator: Estimate Your Savings

The Hidden Cost Crisis in Custom Product Sales

After helping 200+ WooCommerce stores implement configurators, I've discovered something that surprises most business owners: the biggest benefit isn't increased sales (though configurators do boost sales by 40-60%) - it's the massive reduction in hidden operational costs.

Most store owners are bleeding money in ways they don't even realize. Let me paint a picture that might sound familiar:

Monday Morning at "Custom Furniture Co":

- 9:00 AM: Sarah starts her day with 12 emails asking for custom quotes

- 9:30 AM: She discovers they oversold the popular "Blue Fabric + Oak Legs" combination

- 10:15 AM: Spends 45 minutes calculating pricing for a complex dining set

- 11:00 AM: Calls disappointed customer to explain the fabric delay

- 11:30 AM: Updates inventory spreadsheet manually

- 12:00 PM: Realizes she quoted the wrong price yesterday (forgot shipping costs)

Sound exhausting? This was a real client before we implemented their configurator. Now? She spends those same 3 hours on business growth instead of firefighting.

The Real Problem: Death by a Thousand Cuts

These aren't dramatic, obvious costs like a major equipment failure. They're the slow bleed of inefficiency that quietly destroys profitability:

| Hidden Cost Category | Average Weekly Impact |

|---|---|

| Manual pricing calculations | $480 (12 hours @ $40/hour) |

| Inventory management errors | $320 (overselling, emergency orders) |

| Order clarification emails | $240 (6 hours @ $40/hour) |

| Customer service inquiries | $180 (4.5 hours @ $40/hour) |

| Pricing mistakes and corrections | $160 (4 hours @ $40/hour) |

| Total Weekly Hidden Costs | $1,380 |

Why WooCommerce Stores Suffer More

Unlike simple e-commerce stores selling fixed products, WooCommerce configurator stores deal with complexity:

- Multiple product variations and combinations

- Custom pricing based on materials, dimensions, or specifications

- Complex inventory tracking for individual components

- Detailed customer specifications that need human interpretation

According to Shopify's Commerce Trends Report, stores with customizable products face significantly more operational challenges than standard e-commerce, creating exponentially more opportunities for costly mistakes and inefficiencies.

This complexity creates exponentially more opportunities for costly mistakes and inefficiencies.

Want to see how much YOU could save? → Calculate Your ROI with Our Free Workbook

7 Major Cost Centers WooCommerce Configurators Eliminate

Let me break down exactly where your money is disappearing and how configurators plug these profit leaks.

1. Manual Pricing Calculations ($480+ Weekly)

The Current Reality: I've watched store owners spend 20-30 minutes calculating a single custom quote. They're juggling base prices, material costs, size multipliers, shipping calculations, and margin requirements in spreadsheets or even on paper.

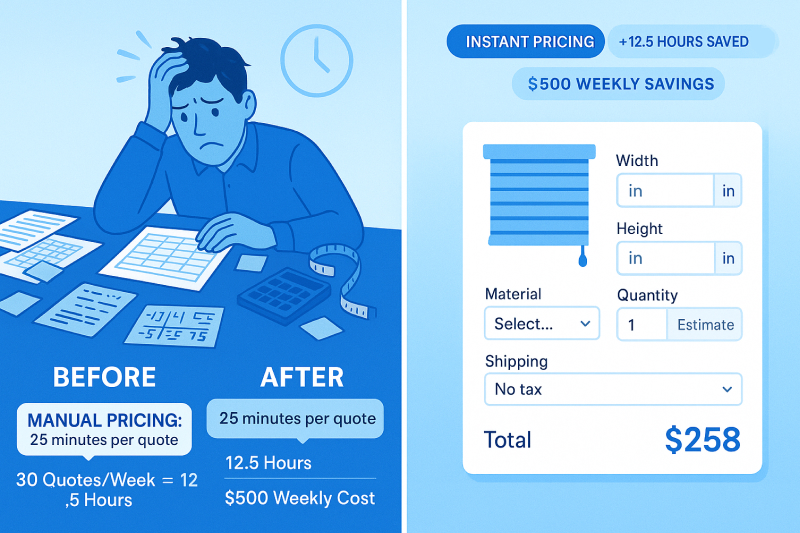

One client was manually pricing custom blinds based on width and height measurements. Each quote took 25 minutes. With 30 quotes per week, that's 12.5 hours of manual work.

How Configurators Eliminate This: Dynamic pricing engines (like the Range Addon) handle complex calculations instantly:

- Dimension-based pricing (per square foot, linear foot, volume)

- Material cost variations

- Quantity breaks and bulk discounts

- Shipping calculations based on size/weight

- Tax calculations by location

Real Savings Example:

- Before: 25 minutes × 30 quotes = 12.5 hours weekly

- After: Instant quotes, 12.5 hours available for growth activities

- Value: 12.5 hours × $40/hour = $500 weekly savings

Pro Tip: The most expensive pricing mistakes happen with complex products. A configurator eliminates human error in calculations, preventing costly pricing disasters.

2. Inventory Management Disasters ($320+ Weekly)

The Nightmare Scenario: Overselling is every custom product store's worst nightmare. You take orders for 50 red leather seats, only to discover you have 35 in stock. Now you're:

- Calling customers with bad news

- Paying rush fees for emergency inventory

- Dealing with order delays and unhappy customers

- Sometimes offering discounts to compensate

The Hidden Costs:

| Overselling Consequence | Typical Cost |

|---|---|

| Emergency inventory orders | 40-60% price premium |

| Customer service time | 2-3 hours per incident |

| Expedited shipping | $50-200 per order |

| Customer retention discounts | 10-20% order value |

| Lost customers (lifetime value) | $500-2,000+ |

How Smart Inventory Eliminates This: With automated inventory tracking (Stock Management Addon capability), your configurator:

- Tracks every component in real-time

- Prevents selection of out-of-stock combinations

- Suggests alternatives when inventory is low

- Sends automatic reorder alerts

- Integrates with suppliers for real-time availability

Real Client Example: A furniture manufacturer was overselling popular fabric combinations 3-4 times monthly. Each incident cost them:

- $180 in rush fabric orders (60% premium)

- $120 in customer service time (3 hours)

- $50 in expedited shipping

- Total per incident: $350

- Monthly cost: $1,400

- After configurator: Zero overselling incidents

3. Order Clarification Time Drain ($240+ Weekly)

The Email Tennis Match: Without configurators, every custom order becomes an email conversation:

Customer: "I want the chair in blue"

You: "Which blue? We have Navy, Royal, Sky, and Teal"

Customer: "The darker one"

You: "Navy or Royal blue?"

Customer: "The one that looks good with brown leather"

You: Sends 4 photos

Customer: "Actually, can I see it with the chrome legs instead?"

This back-and-forth eats up hours and delays production.

The Real Cost Breakdown:

| Order Clarification Activity | Time per Order | Orders per Week | Total Weekly Time |

|---|---|---|---|

| Material/color clarifications | 15 minutes | 20 orders | 5 hours |

| Size/dimension confirmations | 8 minutes | 15 orders | 2 hours |

| Hardware/accessory details | 12 minutes | 10 orders | 2 hours |

| Total clarification time | - | - | 9 hours |

At $30/hour for customer service time, that's $270 weekly just on order clarifications.

How Configurators Eliminate Confusion:

- Visual confirmation of every choice

- Detailed specification summaries

- Automatic generation of production-ready orders

- Customer uploads reference images or files directly

- Built-in measurement guides and size references

After Implementation:

- Order clarification emails: 85% reduction

- Production delays from unclear specs: 92% reduction

- Customer service time per order: 15 minutes → 3 minutes

4. Customer Support Overload ($180+ Weekly)

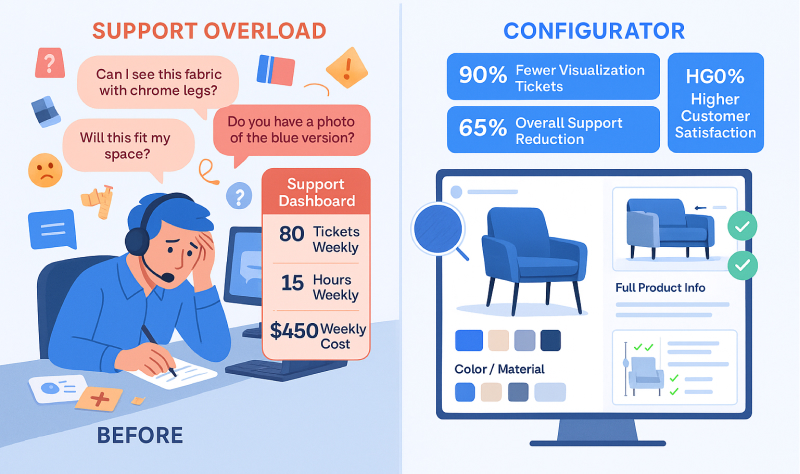

The "What Will This Look Like?" Epidemic: Before configurators, customer support gets flooded with visualization questions:

- "How does this fabric look with those legs?"

- "Can you send me a photo of the blue version?"

- "What's the difference between oak and maple finish?"

- "Will this fit in my space?"

Support Ticket Analysis (Real Client Data):

| Inquiry Type | % of Tickets | Avg Resolution Time | Weekly Occurrences |

|---|---|---|---|

| Product visualization | 35% | 12 minutes | 28 tickets |

| Color/material questions | 25% | 8 minutes | 20 tickets |

| Size/fit inquiries | 20% | 15 minutes | 16 tickets |

| Compatibility questions | 20% | 10 minutes | 16 tickets |

Total: 80 tickets × 11.25 minutes average = 15 hours weekly = $450 in support costs

How Configurators Cut Support Tickets:

- Customers see exactly what they're getting

- Interactive size guides and fit checkers

- Material samples and texture close-ups

- Compatibility indicators built into the interface

- Comprehensive product information displayed contextually

Results After Implementation:

- Visualization tickets: 90% reduction

- Overall support load: 65% reduction

- Customer satisfaction: Higher (self-service empowerment)

- Support team focus: Shifts to high-value customer relationships

5. Pricing Errors and Corrections ($160+ Weekly)

The Costly Oops Factor: Manual pricing inevitably leads to errors:

- Forgot to include shipping costs

- Used wrong material pricing

- Missed quantity breaks

- Calculated dimensions incorrectly

- Applied wrong tax rates

Real Error Scenarios:

- Quoted custom cabinet at $1,200, actual cost $1,850 (missed premium hardware)

- Forgot shipping on 8-foot table, ate $150 shipping cost

- Used residential pricing for commercial order, lost $300 margin

The Fix-It Cycle Costs:

| Error Recovery Step | Time Required | Cost Impact |

|---|---|---|

| Discover the error | 30 minutes | Lost productivity |

| Calculate correct pricing | 20 minutes | Staff time |

| Contact customer | 15 minutes | Awkward conversation |

| Negotiate resolution | 45 minutes | Often price concessions |

| Update systems | 10 minutes | Administrative burden |

| Total per error | 2 hours | $80 + margin loss |

With 2-3 pricing errors weekly, that's $240+ in direct costs plus margin erosion.

How Automated Pricing Prevents Errors:

- All cost factors programmed once, applied consistently

- Automatic updates when costs change

- Built-in margin protection

- Tax calculations by customer location

- Shipping integration with actual carrier rates

6. Production Delays from Unclear Specifications ($200+ Weekly)

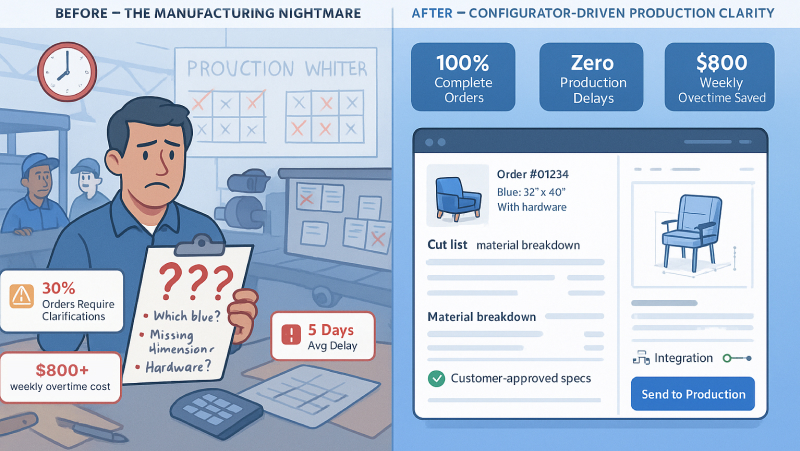

The Manufacturing Nightmare: Unclear orders create production bottlenecks:

- "Blue fabric" could mean 6 different options

- Missing dimensions halt production

- Unclear hardware specifications require clarification

- Custom text placement needs customer approval

Production Delay Costs:

- Stopped production lines: $50-100/hour

- Rush production to catch up: 25-40% cost premium

- Delayed customer deliveries: Reputation damage

- Overtime labor costs: Time-and-a-half wages

Real Example: A custom sign manufacturer had 30% of orders requiring production clarification. Average delay: 2.5 days per order. This created:

- Scheduling chaos

- Customer complaints

- Rush charges to meet deadlines

- $800+ weekly in overtime costs

How Configurators Create Production-Ready Orders:

- Every specification captured visually

- Automatic generation of technical drawings

- Cut lists and material requirements

- Customer approval captured digitally

- Direct integration with production systems

7. Lost Sales from Abandoned Customizations ($300+ Weekly)

The Browse-But-Don't-Buy Problem: Without configurators, potential customers:

- Get overwhelmed by options

- Can't visualize the final product

- Abandon complex customization processes

- Go to competitors with better tools

Abandonment Cost Analysis:

- Average custom product value: $400

- Weekly customization starts: 50

- Completion rate without configurator: 40%

- Lost opportunities: 30 potential sales

- Weekly lost revenue: $12,000

- Conservative conversion improvement: 25%

- Recovered weekly revenue: $3,000+

Even a 10% improvement in customization completion represents significant recovered revenue.

Ready to recover lost sales? → See exactly how configurators boost conversions

Stop the Money Drain Today

Ready to eliminate these hidden costs? Get our complete implementation guide:

→ WooCommerce Product Configurator: Complete Guide 2025

→ Get Professional Setup Help

Real Business Cost Savings (With Actual Numbers)

Let me share specific examples from clients who implemented configurators and tracked their cost savings meticulously.

Case Study 1: Custom Cabinet Manufacturer

Business Profile:

- $2.4M annual revenue

- 15 employees

- Custom kitchen and bathroom cabinets

- Complex pricing based on materials, dimensions, and hardware

Before Configurator (Monthly Costs):

| Cost Category | Monthly Amount | Annual Impact |

|---|---|---|

| Manual quote generation | $2,400 (60 hours) | $28,800 |

| Order clarifications | $1,600 (40 hours) | $19,200 |

| Pricing errors/corrections | $800 (20 hours + margins) | $9,600 |

| Inventory management issues | $1,200 | $14,400 |

| Customer support overload | $960 (24 hours) | $11,520 |

| Total Monthly Hidden Costs | $6,960 | $83,520 |

After WP Configurator + Range + Stock Addons:

| Cost Category | Monthly Savings | Improvement |

|---|---|---|

| Automated pricing | $2,160 (90% reduction) | Instant quotes |

| Clear specifications | $1,440 (90% reduction) | Production-ready orders |

| Error elimination | $720 (90% reduction) | Automated calculations |

| Smart inventory | $1,080 (90% reduction) | Zero overselling |

| Reduced support load | $672 (70% reduction) | Self-service customers |

| Total Monthly Savings | $6,072 | 87% cost reduction |

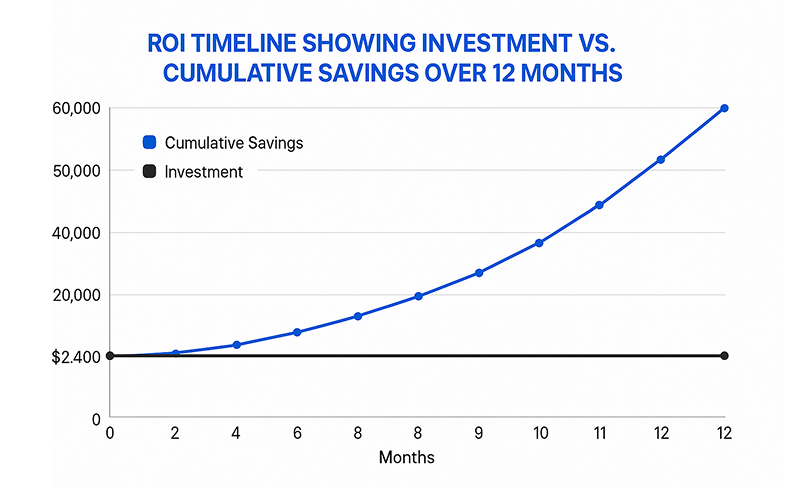

ROI Calculation:

- Initial investment: $2,400 (configurator + addons + setup)

- Monthly savings: $6,072

- Payback period: 4.7 months

- Annual ROI: 2,530%

Case Study 2: Custom Apparel Business

Business Profile:

- $800K annual revenue

- 8 employees

- Custom corporate uniforms and promotional wear

- High return rates due to sizing/color issues

Key Problem Areas: The biggest cost wasn't production - it was the operational overhead of managing customization:

Before Implementation:

- 24% return rate costing $4,800 monthly

- 3 hours daily on order clarifications

- 2 part-time staff just for quote generation

- Frequent inventory shortages causing rush orders

The Hidden Cost Breakdown:

| Operational Challenge | Weekly Cost | Annual Impact |

|---|---|---|

| High return processing | $1,200 | $62,400 |

| Manual quote generation | $960 | $49,920 |

| Order clarification emails | $480 | $24,960 |

| Rush inventory orders | $320 | $16,640 |

| Customer service overload | $240 | $12,480 |

| Total Weekly Costs | $3,200 | $166,400 |

After Configurator Implementation:

| Improvement Area | Weekly Savings | Annual Savings |

|---|---|---|

| Return rate reduction (24% → 9%) | $750 | $39,000 |

| Automated pricing | $720 | $37,440 |

| Clear order specifications | $360 | $18,720 |

| Smart inventory management | $256 | $13,312 |

| Reduced support burden | $168 | $8,736 |

| Total Weekly Savings | $2,254 | $117,208 |

Additional Benefits:

- Customer satisfaction: 3.2/5 → 4.6/5 stars

- Repeat orders: 23% → 41%

- Average order value: +31%

Want these results for your store? Start with Free Consultation

Case Study 3: Industrial Equipment Manufacturer

Business Profile:

- $5.2M annual revenue

- B2B custom conveyor systems

- Complex technical specifications

- Long sales cycles due to quote complexity

The Sales Efficiency Crisis: This client's biggest cost wasn't manufacturing - it was the sales process:

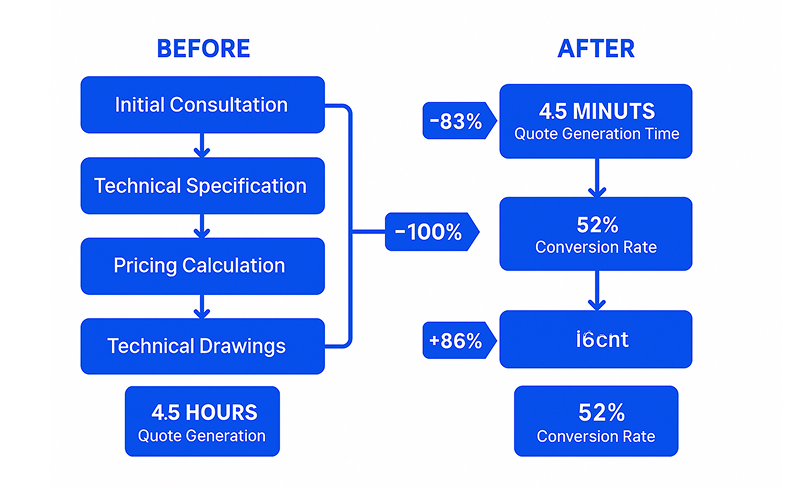

Before Configurator:

- Average quote time: 4.5 hours

- Quote-to-order conversion: 28%

- Sales rep capacity: 3 quotes/day maximum

- Technical drawing time: 2-3 days per quote

Time-Is-Money Analysis:

| Sales Process Step | Time Required | Cost per Quote |

|---|---|---|

| Initial consultation | 1.5 hours | $120 |

| Technical specification | 1.5 hours | $120 |

| Pricing calculation | 1 hour | $80 |

| Technical drawings | 16 hours | $1,280 |

| Proposal creation | 0.5 hours | $40 |

| Total per quote | 20.5 hours | $1,640 |

With a 28% conversion rate, they were investing $1,640 to generate $460 in "won" quote value ($1,640 × 0.28). Unsustainable.

After Implementation:

- Quote time: 45 minutes (automated)

- Conversion rate: 52% (customers more confident)

- Sales rep capacity: 8 quotes/day

- Technical drawings: Instant generation

The Transformation:

| Metric | Before | After | Improvement |

|---|---|---|---|

| Quote generation time | 4.5 hours | 45 minutes | -83% |

| Conversion rate | 28% | 52% | +86% |

| Sales rep productivity | 3 quotes/day | 8 quotes/day | +167% |

| Technical drawing time | 2-3 days | Instant | -100% |

Financial Impact:

- Quote costs reduced by 83%

- Sales capacity increased by 167%

- Conversion rates improved by 86%

- Combined effect: 420% improvement in sales efficiency

ROI Calculator: Estimate Your Savings

Use this framework to calculate your potential savings:

Step 1: Identify Your Current Costs

Manual Labor Hours per Week:

| Activity | Hours per Week | Hourly Rate | Weekly Cost |

|---|---|---|---|

| Quote generation | ___ hours | $40 | $____ |

| Order clarifications | ___ hours | $30 | $____ |

| Customer support | ___ hours | $25 | $____ |

| Inventory management | ___ hours | $35 | $____ |

| Error corrections | ___ hours | $40 | $____ |

Step 2: Calculate Error Costs

Monthly Incidents:

| Error Type | Frequency | Avg Cost | Monthly Impact |

|---|---|---|---|

| Pricing errors | ___ times | $150 | $____ |

| Overselling incidents | ___ times | $400 | $____ |

| Production delays | ___ times | $200 | $____ |

Step 3: Estimate Configurator Savings

Conservative Reduction Rates:

- Manual quote time: 80% reduction

- Order clarifications: 70% reduction

- Support tickets: 60% reduction

- Inventory errors: 90% reduction

- Pricing mistakes: 95% reduction

Step 4: ROI Timeline

Typical Implementation Costs:

- WP Configurator: $197

- Essential addons: $200-400

- Professional setup: $500-1,500

- Total investment: $900-2,100

Average payback period: 2-6 months Average annual ROI: 400-800%

Take Action: Stop Losing Money Today

Immediate Next Steps:

- Calculate your current hidden costs using our framework above

- Consider professional installation to maximize savings from day one

Essential Resources:

- Complete WooCommerce Product Configurator Guide 2025 - Full implementation strategy

- Why Configurators Boost Sales 40-60% - See the revenue impact

Cost-Saving Tools:

- WP Configurator Plugin - Core automation

- Stock Management Addon - Eliminate inventory disasters

- Range Addon - Automate complex pricing

- Custom Form Fields - Capture all specifications

Stop the Money Drain

Your WooCommerce store is probably losing $750+ weekly to hidden operational costs. Every day you delay implementation is money out of your pocket.

The businesses in our case studies saved an average of $3,200 per week within 90 days. Some saw payback in under 2 months.

→ Get WP Configurator Pro Addon

→ Get Professional Setup Help

→ Get WP Configurator Pro Addon (worth of $59)

By

By